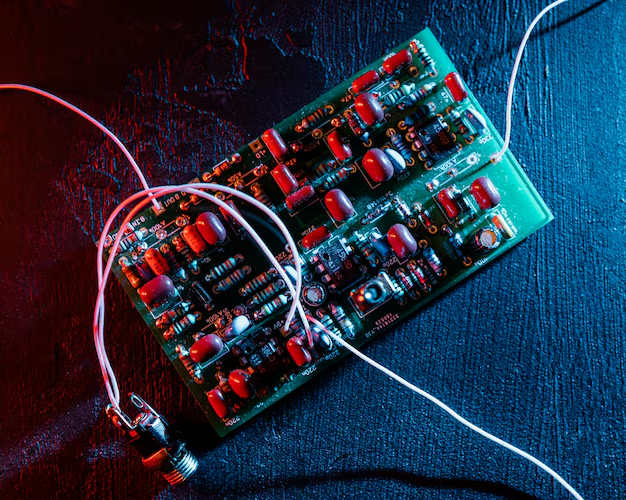

Introduction to Printed Circuit Board Transformers

A Printed Circuit Board Transformer is an essential component in modern electronic devices, offering efficient voltage conversion, electrical isolation, and compact integration into circuit designs. Unlike traditional transformers, PCB transformers are directly mounted onto printed circuit boards, making them ideal for applications requiring miniaturization and high efficiency.

How a PCB Transformer Works

A PCB transformer operates on the principle of electromagnetic induction, where alternating current (AC) in the primary coil generates a magnetic field that induces voltage in the secondary coil. These transformers use laminated cores, ferrite cores, or planar structures to optimize performance in compact electronic circuits. The core material and winding techniques significantly affect the transformer’s efficiency, power handling, and electromagnetic interference (EMI) characteristics.

Types of PCB Transformers

1. Laminated Core PCB Transformers

Laminated core transformers are made from thin layers of silicon steel laminated together to reduce eddy current losses. These are commonly used in low-frequency applications and offer reliable performance.

2. Ferrite Core PCB Transformers

Ferrite core transformers utilize ferrite material, which exhibits low core losses at high frequencies. These are preferred in high-frequency applications such as switch-mode power supplies (SMPS) and RF circuits.

3. Planar PCB Transformers

Planar transformers leverage flat copper windings embedded in PCB layers instead of traditional wire windings. They offer:

- Improved thermal performance

- Higher power density

- Low profile designs

- Reduced parasitic losses

Advantages of Using PCB Transformers

1. Compact and Space-Efficient

PCB transformers are integrated into circuit boards, eliminating bulky external components and reducing overall device size.

2. High Efficiency and Low Power Losses

With optimized winding structures and ferrite cores, PCB transformers minimize energy loss, leading to enhanced power conversion efficiency.

3. Improved Thermal Management

Planar PCB transformers distribute heat more effectively, ensuring lower operating temperatures and extended component lifespan.

4. Enhanced Electrical Isolation

PCB transformers provide galvanic isolation, ensuring safety in high-voltage applications and preventing electrical faults.

5. Cost-Effective Manufacturing

By integrating directly into the PCB layout, these transformers eliminate additional assembly steps, reducing production costs.

Applications of PCB Transformers

1. Power Supplies

PCB transformers are widely used in switch-mode power supplies (SMPS), DC-DC converters, and AC-DC adapters, offering efficient voltage regulation.

2. Medical Devices

Due to their electrical isolation properties, PCB transformers are ideal for medical electronics, ensuring safety in life-support systems.

3. Telecommunications

In networking equipment and signal processing systems, PCB transformers help in impedance matching and noise isolation.

4. Automotive Electronics

Modern vehicles incorporate PCB transformers in battery management systems, inverters, and EV charging circuits, enhancing performance and energy efficiency.

Design Considerations for PCB Transformers

1. Core Material Selection

Choosing the right core material (e.g., ferrite, powdered iron, or laminated steel) is crucial for optimizing efficiency and minimizing electromagnetic interference (EMI).

2. Winding Configuration

- Copper traces in PCB layers reduce resistance and inductance.

- Multi-layer winding structures improve coupling and thermal dissipation.

- Shielding techniques help mitigate EMI issues.

3. Insulation and Safety Compliance

To ensure regulatory compliance (e.g., UL, IEC, and ISO certifications), designers must adhere to creepage and clearance distance guidelines.

4. Operating Frequency Optimization

High-frequency designs require low-loss cores and optimized winding structures to enhance performance and minimize skin and proximity effects.

Challenges in PCB Transformer Design

1. Thermal Management Issues

Heat dissipation is critical in high-power applications. Solutions include:

- Heat sinks

- Enhanced PCB layout techniques

- Forced air cooling

2. EMI and Noise Interference

PCB transformers can introduce electromagnetic interference (EMI), impacting signal integrity. Mitigation strategies include:

- Shielding techniques

- Optimized winding structures

- Filtering components

3. Manufacturing Complexity

Advanced PCB transformers, such as planar types, require precise fabrication techniques, increasing production complexity.

Future Trends in PCB Transformers

1. Miniaturization and Higher Efficiency

Ongoing advancements in nanocrystalline core materials and high-frequency switching technologies are pushing the limits of PCB transformer efficiency.

2. Integration with Smart Electronics

PCB transformers are becoming integral to IoT devices, smart sensors, and AI-driven electronics, enabling efficient power management and signal isolation.

3. Enhanced Sustainability

The industry is shifting towards eco-friendly materials and energy-efficient designs, reducing the environmental impact of PCB transformers.

Conclusion

A Printed Circuit Board Transformer is a vital component in modern electronics, offering compact design, high efficiency, and excellent electrical isolation. Whether used in power supplies, medical equipment, or automotive applications, PCB transformers enhance performance while reducing size and cost. Engineers and designers must carefully consider core materials, winding techniques, and thermal management to optimize transformer performance.

For the latest advancements and expert insights, staying updated on PCB transformer technologies is crucial for designing next-generation electronic systems.